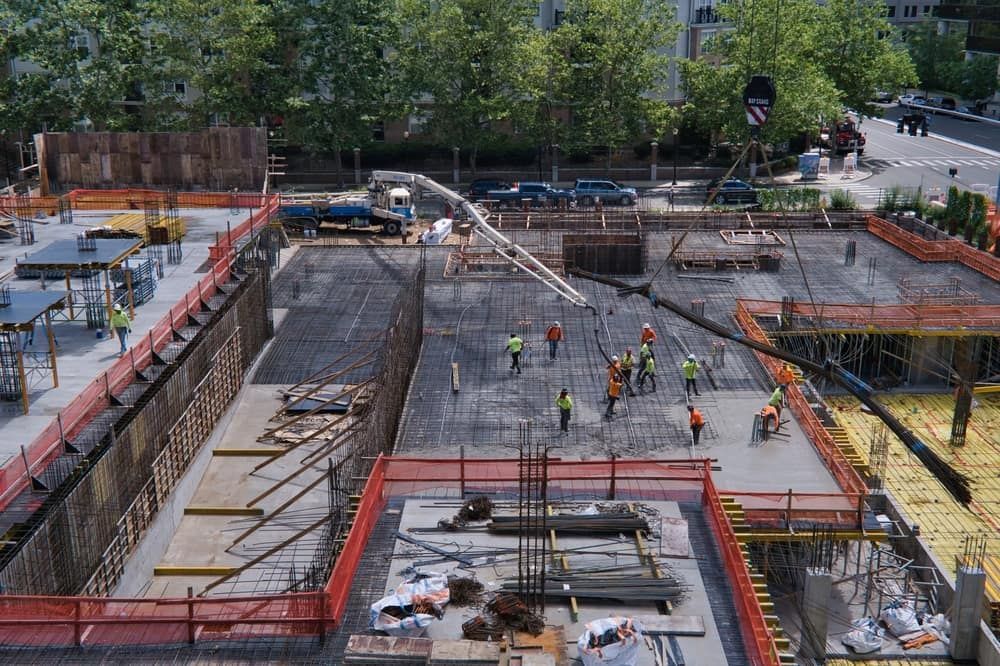

What are Common Construction Site Hazards & How Can They Be Prevented?

Safety is the top priority in every successful construction project. Getting caught between heavy machinery, falls from heights, chemical exposure, and electrocution can result in fatal injuries, work stoppage, lawsuits, and financial liabilities.

However, prioritizing worksite safety requires continual monitoring, training, compliance, and protective equipment procurement, which can be a lot to handle alone. Partnering with experienced construction management firms helps owners coordinate daily

worksite safety

without interfering with deliverables and construction timelines.

Let’s examine some common construction site hazards and the proactive steps to keep workers protected.

Why Safety Is Critical in Construction Projects

Accidents and injuries on construction sites can be traumatizing for owners and workers. Besides taking toll on the owner’s sanity, construction fatalities trigger lawsuits, prolonged OSHA investigations, and financial liabilities, which disrupt operations and project timelines. Even after construction resumes, workers might not feel safe, which negatively impacts morale and productivity.

Implementing safety measures for your construction projects protects the contractors and guarantees operational stability. By complying with OSHA standards, providing the right equipment, and educating contractors on proper equipment usage, you can have construction sites where the workforce feels safe to perform tasks.

Common Construction Hazards & Prevention Methods

In 2023, the United States recorded 5,283 cases of fatal work injuries. Identifying frequent construction dangers and taking proactive measures for worksite safety helps project owners create a safe workplace for construction workers.

Let’s examine some common hazards and how to prevent them:

Fall Hazards

Falls occur frequently on construction sites. The Bureau of Labor Statistics recorded 47.8% of fatal falls in 2023 from the construction industry. These accidents could have been avoided by addressing common hazards such as unprotected edges, unstable scaffolding, improper ladder use, and slippery surfaces.

According to the Occupational Safety and Health Administration (OSHA), providing the right equipment can also help keep construction workers safe, such as ladders, scaffolds, hard hats, safety boots, and face shields. Project owners should provide orientation on safety procedures, equipment setup, and protective systems usage while on the job. In accordance with OSHA standards, clear fall protection signage should be used to mark high-risk areas, helping workers identify and avoid potential hazards.

Electrocution

Electrocution is another prevalent construction site hazard. According to OSHA, 61% of all US workplace electrocutions were construction-related. It is usually caused by an exposed live wire, extension cords carelessly running through the site, or a buried power cut during excavation.

Construction leads can prevent electrocution by inspecting the proper insulation, using safe grounding methods, marking, and securing dangerous areas. Workers should be trained to safely handle electrical equipment and identify potential hazards, such as exposed outlets or frayed wires. Implementing a safety program entails wearing boots, gloves, face shields, and long-sleeved garments, which also reduces the risk of burns or electrocution.

Struck-By Hazards

Struck-by injuries occur from a violent impact with moving objects or heavy machinery. Although heavy machinery, such as cranes and trucks, enhances productivity, they are responsible for approximately 75% of struck-by fatalities in construction. Struck-by hazards can, unfortunately, result in loss of life or a limb.

Project owners can prevent this construction hazard by adopting proactive safety measures. Contractors should always wear proper personal equipment (PPE), including a hard hat and steel-toe boots. Only trained personnel should be allowed to operate heavy machinery, and safety devices should be inspected before use. Operators should also avoid overloading heavy equipment, such as cranes and forklifts, beyond their maximum capacity to prevent malfunctions and serious accidents.

Additionally, maintaining order and preventing collisions between vehicles and pedestrians should be the top priority in construction sites. That’s why forklift safety signs should be used to direct traffic, designate pedestrian zones, and warn of blind spots.

Chemical Hazards

Construction workers are often exposed to various chemical substances, including paints, coatings, adhesives, solvents, and asbestos, on construction sites. These hazardous substances can be dangerous to health, causing eye damage, respiratory problems, skin burns, and irritation.

Properly labeling a hazardous chemical container prevents accidental exposure and allows quick emergency response. Labels should comply with OSHA’s

Hazard Communication Standard Pictogram, which suggests using signal words (like danger or warning) on the chemical substances. There should also be a proper procedure for storing, transferring, mixing, and disposing of hazardous chemicals.

Prioritize Construction Safety with EDC

Juggling numerous safety protocols, OSHA standards, contractor training, equipment provision, and inspecting while delivering smooth operation can be a lot to handle. By entrusting construction safety to EDC, you can focus on other important tasks.

At EDC, our team keeps worksite safety front and center throughout with proactive planning, proper equipment selection, compliance, and continuous workforce orientation. Partnering with EDC minimizes risks, complies with OSHA standards, and guarantees every worker returns home safely at the end of the day.

Contact EDC today, and let’s build a safer construction site together.