Key Considerations for Warehouse Construction Projects

Warehouse projects are built to support the storage, distribution, and logistics of commercial goods. However, owners are expected to make decisions, such as site selection, building materials, and regulatory standards, that impact the performance, durability, and operational efficiency of the warehouse facility. With a construction management team by your side, you leverage the expertise needed to make informed decisions and avoid costly mistakes.

In this article, we’ll examine why

warehouse construction requires a specialized approach and the essential considerations for building an efficient, high-performing facility.

Why Warehouse Construction Requires a Specialized Approach

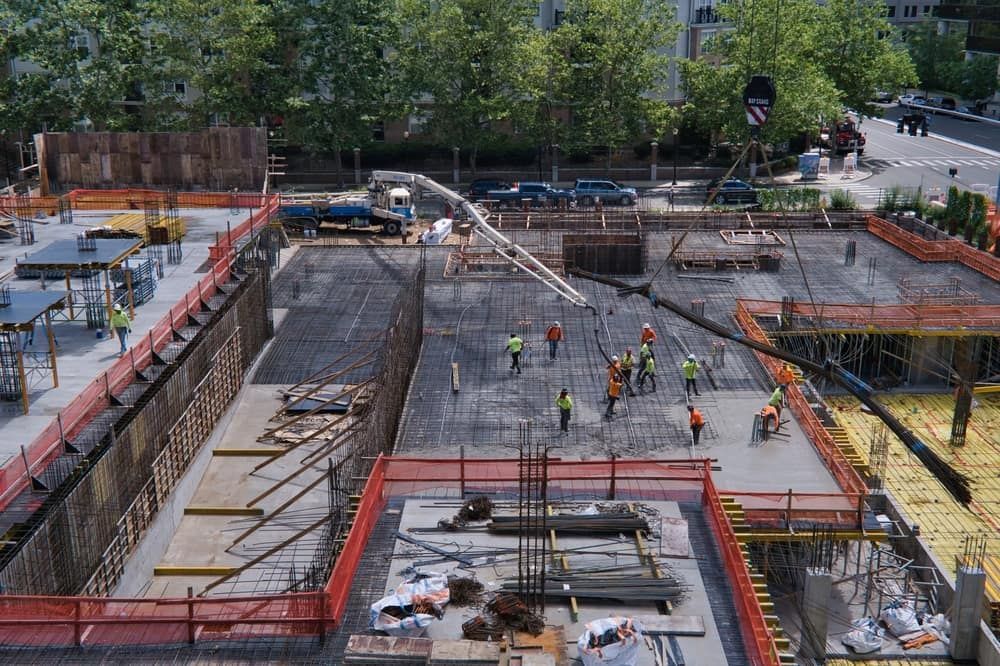

Building a warehouse structure that facilitates logistics and operational efficiencies goes beyond putting up walls and a roof. It requires a specialized approach where functionality, safety, and efficiency precede aesthetics.

For

safety and stability, warehouse facilities are built with heavy loads, frequent machine movements, and large-scale storage in mind. The structure usually has high ceilings, wide bays, loading docks, and unobstructed floors to accommodate forklifts, pallet racks, and conveyor systems.

Prioritizing factors like site selection, building materials, future scalability, and safety standards guarantees the warehouse is durable, efficient, and evolves with operational needs.

Top Considerations for Planning and Managing Warehouse Construction

To build a warehouse that supports long-term operations and growth, project owners need to prioritize these key factors:

Building Material

Every successful warehouse project starts with choosing the right materials, not always costly ones. Low-quality materials can’t withstand heavy loads or environmental impacts, leading to cracks, leaks, and premature deterioration. Similarly, the use of costly but unsuitable materials leads to wasted resources and budget overruns.

Structural steel champions in durability, sturdiness, and resistance against extreme weather conditions. Steel can withstand tornadoes, hurricanes, and heavy snow loads. It also lets owners cut costs on maintenance and repairs. At the end of its lifecycle, Steel is

100% recyclable without losing any properties.

Likewise, metal roofing stands out for its lifespan and low maintenance.

The Metal Construction Association reported that metal roofs can last up to at least 60 years. Woods are not a popular option for warehouse construction because they’re highly flammable and prone to rot and pests. However, woods are still utilized for shelving spaces.

Concrete is usually used for warehouse flooring. It has a compressive strength that effortlessly handles heavy loads. It supports vehicle traffic from pallet jacks and forklifts, which move around daily.

Site Selection

A warehouse isolated from transportation routes will likely derail delivery timelines and increase operational costs. Strategic site selection is crucial for optimal distribution, trucks and vehicles accessibility, and potential future expansion.

Warehouse proximity to vendors and customers reduces transportation costs and speeds up delivery. A warehouse construction site accessible to major roads, seaports, airports, and rail terminals guarantees seamless truck movements and

intermodal connectivity.

Hidden site issues, such as high groundwater, poor soil, steep slopes, and proximity to hazardous facilities, can drive up costs, delay construction, and result in liabilities. To avoid these setbacks, inspect the site and make sure it meets zoning requirements early on. Project owners should also acquire a site with enough square footage for current and future storage needs.

Compliance Standards

Compliance with regulatory standards eliminates risks like work stoppage, lawsuits, costly fines, and worksite hazards. In the US, local zoning requirements, building codes, and environmental regulations vary across states. Not only that, the International Code Council (ICC) updates building codes every 3 years.

Juggling regulatory standards complexities can be a lot to handle alone. However, entrusting construction management firms like

EDC with your compliance obligations allows you to focus on important tasks. The partnership lets you stay up-to-date and compliant with regulatory standards, such as the

International Building Codes (IBC),

Occupational Safety and Health Regulations (OSHA), and

National Fire Protection Association (NFPA) standards.

Future Scalability and Adaptability

Building warehouse facilities with a scalable mindset guarantees that the structure can easily adapt to business changes without operational disruption or costly renovations.

A great place to start is leveraging data analytics to forecast future needs and plan warehouse construction accordingly. With this mindset, businesses occupying the facilities can anticipate growth opportunities and scale up their operations.

Owners can also make plans for future needs by acquiring extra land for expansion, prioritizing a modular storage system, and incorporating flexible layouts.

Plan Your Warehouse Construction Project with Confidence

Smart planning and construction choices determine how effectively a warehouse handles heavy loads, constant equipment movement, and expanding distribution needs. Partnering with EDC helps align every decision with logistics workflows, reduce construction risks, and support long-term scalability.

Our team also guarantees seamless navigation of complex regulatory standards and deliverables without derailing the construction progress. From building new facilities to expanding existing ones, EDC brings the experience, expertise, and teamwork needed to deliver results and exceed expectations.

Start your project on the right track.

Connect with EDC today to build a high-performing warehouse that’s delivered on time and designed to last.